- Use:

-

texturing machinery

- Type:

-

Barmag yarn sensor

- Warranty:

-

Unavailable

- Condition:

-

New

- Applicable Industries:

-

Machinery Repair Shops, Retail, Other, textile spare parts

- Weight (KG):

-

0.05

- Video outgoing-inspection:

-

Not Available

- Machinery Test Report:

-

Not Available

- Marketing Type:

-

Ordinary Product

- Place of Origin:

-

Zhejiang, China

- Brand Name:

-

topt

- Material:

-

plastic

- package:

-

single piece package

- Quality:

-

guaranteed

- Color:

-

white

- Name:

-

Barmag yarn sensor

- Machine Type:

-

Texturizing machinery parts

- Shiping:

-

by courier /air / sea

- Delivery time:

-

3-5 Working Days

- Payment Term:

-

T/T, Paypal, Western Union

- Service:

-

24 hours on-line service

Instruction:

The wire detector is installed behind the oil tanker and is composed of a contact capacitive sensor. When the wire is broken before winding, there is no wire passing through the wire detector, and the capacitance value is different from that when the wire passes, so as to send a signal to let the wire cutter work, cut off and clamp the feed such as raw wire.

Precautions:

1. Check whether the wire detector and wire cutter fail.

2. Whether the wire detector is loose and not in place.

3. Whether the wire detector and front wire guide are blocked.

4. Whether the wire detector is damaged by oil agent 5 Whether the change-over switch of wire cutter is normal.

Wire hanging process:

Wire frame – wire cutter – roller (FRI) – raw rod wire guide – first heating box – cooling plate – false twister – tensioner – second roller (FR2) – Network nozzle – second roller (afr2a) – second heating box – third roller (FR3) – wire detector (wire sensor) – oil tanker – winding forming device

Specification:

| Remark: | Barmag | Application: | texturing machinery |

| Name: | Barmag yarn sensor | Color: | metal |

Products Image:

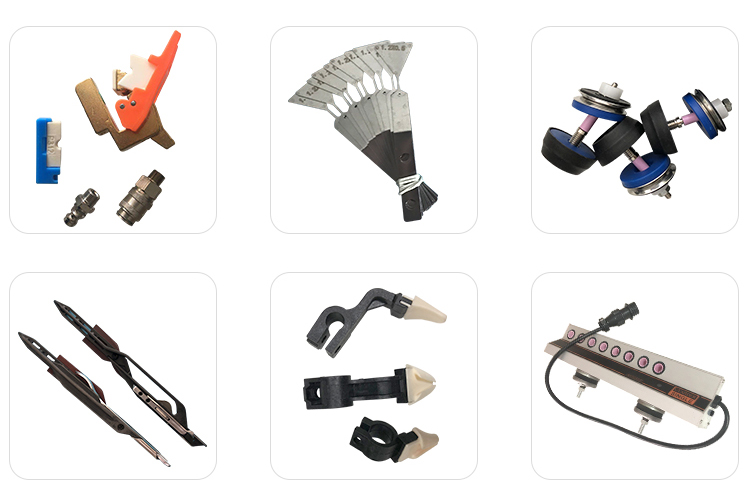

Other BARMAG Texturizing machinery parts:

Packing and Delivery:

1.Carton package suitable for air and sea shipment.

2.Delivery normally is one week.

Contact us:

· Website:http://topt-textile.en.alibaba.com

· Contact: Sally Wang

· Cellphone: 0086 18506266628

· whatsapp: +008618506266628

· wechat:008618506266628

WE WILL KEEP YOU INFORMED OF OUR NEWEST PRODUCTS & WELCOME TO CONTACT US AT ANY TIME!